Siemens AG (UK) - New rules require far-reaching changes to car and Infiniti Red Bull Racing relying on Siemens software.

For record speeds both on and off the track, Infiniti Red Bull Racing is relying on Siemens software once again this season. At the team's factory in Milton Keynes, UK, over 100 engineers are using Siemens software to redevelop the world champion racecar for Sebastian Vettel and Daniel Ricciardo. New rules issued for the 2014 Formula One season by the FIA, motorsport's global governing body, mandate wide-ranging changes in the car's design. Siemens' product lifecycle management (PLM) software is helping ensure their rapid implementation.

"In the racing business, time and reliability are the key success factors. Minimal changes in a car's construction can impact its entire performance. Our PLM software is enabling the engineers at Infiniti Red Bull Racing to accelerate product design and production processes, achieving more design iterations in the virtual environment than could ever be achieved physically," explained Siegfried Russwurm, CEO of Siemens' Industry Sector and member of the company's Managing Board. "But PLM software isn't just a plus for Formula One," he added. "Our customers can use it in almost every industry – from ski design to industrial production."

The Siemens software allows Infiniti Red Bull Racing engineers to design new car components, test them in the virtual domain and initiate their production and installation with a mouse click in record time. "The Siemens partnership is a critical one for us because it's an integral part of our design process. Through our relationship with Siemens we've come to rely on their critical tools to generate creative design solutions, thus ensuring that we field the best grand prix cars we possibly can. In no small part Siemens has been a key contributor to our success in recent years, and the eight world championships we have achieved," states Christian Horner, Team Principal, Infiniti Red Bull Racing.

Later modifications can, of course, also be made quickly. To adapt the racecar to individual track conditions, developers can simulate a wide range of variants on the computer in order to find the ideal configuration. Both in the factory and at the track, engineers have access to all the design data they need to continuously monitor the results of changes to the vehicle.

Siemens PLM Software, a Business Unit of the company's Industry Automation Division, is a leading global supplier of product lifecycle management (PLM) software and related services, with seven million licensed users and more than 71,000 customers around the world. Its industry software offerings provide Siemens with a platform that can transform companies in a wide variety of industries into digital enterprises.

The platform makes possible the full digital imaging and digital processing of every step in the product creation process. Today, industry software from Siemens is used for everything from adapting the front wings of Formula One racecars to particular track conditions and optimizing the complete car-making process to seamlessly monitoring every component in electronics manufacturing.

Siemens industry software enables companies to get products to the market faster, tailor offerings to individual customer requirements more precisely than ever before and continuously improve productivity and efficiency. With its industry software, Siemens is setting the pace in the digitization of manufacturing and thus enhancing quality and reliability.

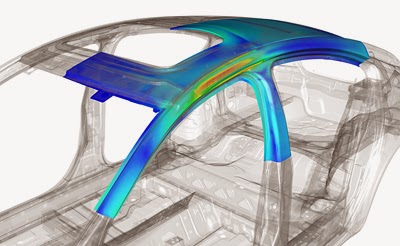

Picture caption:

Advanced Simulation - Siemens NX solution for simulation include NX CAE, which is a modern, multi-discipline CAE environment for advanced analysts, workgroups, and designers who need to deliver high quality performance insights in a timely fashion to drive product decisions.

About Siemens AG (Berlin and Munich):

Siemens AG is a global powerhouse in electronics and electrical engineering, operating in the fields of industry, energy and healthcare as well as providing infrastructure solutions, primarily for cities and metropolitan areas. For over 165 years, Siemens has stood for technological excellence, innovation, quality, reliability and internationality. The company is one of the world's largest providers of environmental technologies. Around 43 percent of its total revenue stems from green products and solutions. In fiscal 2013, which ended on September 30, 2013, revenue from continuing operations totaled €75.9 billion and income from continuing operations €4.2 billion. At the end of September 2013, Siemens had around 362,000 employees worldwide on the basis of continuing operations.

This website uses cookies. By browsing our website you accept the use of cookies. For more information read our Terms of Use.

Siemens PLM helping design new Formula One racer

- By Siemens

- Posted on Mar 20, 2014

For more information about this article from Siemens click here.

Interesting Links:

GameMarket.pt - Your Gaming Marketplace with Video Games, Consoles, PC Gaming, Retro Gaming, Accessories, etc. !

Are you interested on the Weighing Industry? Visit Weighing Review the First and Leading Global Resource for the Weighing Industry where you can find news, case studies, suppliers, marketplace, etc!

Are you interested to include your Link here, visible on all AutomationInside.com articles and marketplace product pages? Contact us

GameMarket.pt - Your Gaming Marketplace with Video Games, Consoles, PC Gaming, Retro Gaming, Accessories, etc. !

Are you interested on the Weighing Industry? Visit Weighing Review the First and Leading Global Resource for the Weighing Industry where you can find news, case studies, suppliers, marketplace, etc!

Are you interested to include your Link here, visible on all AutomationInside.com articles and marketplace product pages? Contact us

© Siemens / Automation Inside

Previous article

Spacial.conf software from Schneider Electric puts convenience into the configuration and quotation of enclosures

Next article

Hannover Messe Germany 2014

Popular News

Automation Inside Newsletter

Popular Tags

Login

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.