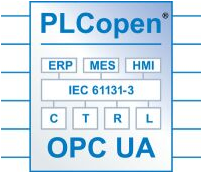

PLCopen (Netherlands) - OPC-UA Client Function Blocks for IEC 61131-3.

In October 2008 the cooperation between PLCopen and OPC Foundation started with a kick-off to map the IEC 61131-3 Software Model to the OPC UA information model, which was released in March 2010 by both organizations. The basis was provided by the OPC UA Client – Server architecture for which the server is integrated in or connected to the controller with a link to the extended program and controller information as provided by the PLCopen / IEC 61131-3 mapping.

From the beginning it was clear that the mapping of IEC 61131-3 into OPC UA server in the controller was only the first step. So in 2011 the working groups initiated the next step by adding the OPC UA client functionality in the controller by defining a set of Function Blocks for IEC 61131-3. This specification was released on April 3rd 2014.

With this specification the controller becomes an intelligent part in the IT communication. The interaction between IT and the industrial automation level is often represented by the established model of the automation pyramid:

In terms of communication, this model represents the assumption that a controller, as a main component of the automation system, is “dumb” towards the higher level, and only responds to requests from these higher levels. The higher level is always the client and initiates the data requests – the lower layer is always the server and courteously responds to the requests. In the modern world this strict separation of levels, as well as the top-down approach of the information flow, is softened and more and more a flat models appear.For instance, in a smart network every device or service must be able to initiate independent communication with all other services.

The result of the working group is about OPC-UA client functionality out of the IEC 61131-3 controller: A controller can exchange complex data structures horizontally with other controllers independently from fieldbus system or vertically with other devices using an OPC-UA server call in an MES/ERP system in order to collect data or write new production orders to the cloud. It allows a production line to be independently active in combination with integrated OPC UA Security features.

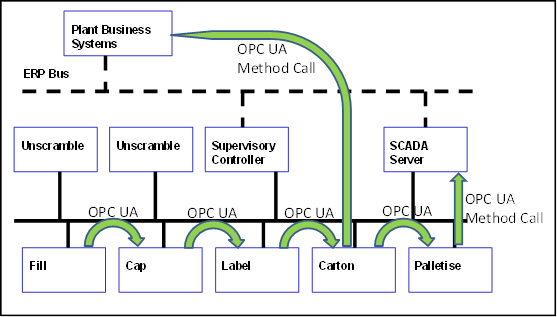

If one looks to a production line one can easily see where this functionality fits in. For example in the production line hereunder the different machines can communicate to each other via the client – server architecture. Moreover, with e.g. the Method call they can invoke a service in a system on a higher level, and for instance get a production recipe for the product at hand very efficient with just one single call exchanging input and output parameters.

An OPC-UA client functionality in a controller does not provide hard deterministic real time and so it’s not a deterministic fieldbus – but OPC UA provides fast and secure fieldbus independent communication, and provides modelling mechanism for information models.

Quotes:

Eelco von der Wal, Managing Director of PLCopen:

“Communication is not about data. Communication is about information and access to that in an easy and secure way. This is what the cooperation PLCopen and OPC Foundation is all about. OPC UA technology creates the possibility for a transparent communication independent of the network, which is the foundation for a new communication age in industrial control.”

Stefan Hoppe, Product Manager TwinCAT, Beckhoff initiated the idea of PLCopen FB’s early during first OPC-UA developer conference in October 2006. “I am happy and proud to see this specification being released but more important been adopted in the industry: BECKHOFF, B&R, Bosch-Rexroth and Omron supported the group with prototype implementations and will provide products within one year. Also 3S announced the functionality available within 2 years.”

Details will be presented at OPC Day Europa “IT meets Automation” – 14-15 May 2014 at Festo, Esslingen, Germany.

About PLCopen:

PLCopen was founded in 1992 as an independent worldwide association for industrial suppliers and users. It is the leading association resolving topics related to industrial control programming. PLCopen creates concepts to reduce the costs of industrial automation. These cost savings are realized in areas such as engineering, training, operation and maintenance. Together with its members, PLCopen creates specifications to materialize these concepts.

About OPC Foundation:

The OPC Foundation defines standards for online data exchange between automation systems. They address access to current data (OPC DA), alarms and events (OPC A&E) and historical data (OPC HDA). Those standards are successfully applied in industrial automation.

The new OPC Unified Architecture (OPC-UA) unifies the existing standards and brings them to state-of-the-art technology using service-oriented architecture (SOA). Platform-independent technology allows the deployment of OPC-UA beyond current OPC applications only running on Windows-based PC systems. OPC-UA can also run on embedded systems as well as Linux / UNIX based enterprise systems. The provided information can be generically modelled and therefore arbitrary information models can be provided using OPC-UA.

Source Link

Other Articles from PLCopen (Netherlands)

Other Articles from OPC Foundation (USA)

© PLCopen (Netherlands) / Automation Inside

Joined PLCopen and OPC Foundation technical working group releases next step in transparent communication

- By PLCopen

- Posted on Apr 11, 2014

For more information about this article from PLCopen click here.

© PLCopen / Automation Inside

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.