Axians Industrial Applications & Services GmbH (Germany) - Author: Reiner Bachthaler.

Shipping automation plays a crucial role in the sand and gravel industry. And while truck loading at the silo has often already been automated, loading with wheel loaders is usually still completely manual. In this blog post, we will take an in-depth look at the challenges of this shipping process and the solutions to optimize it.

The current challenge: Manual loading process for bulk material on the wheel loader:

In many sand and gravel plants, loading with wheel loaders is still a manual process. Information about the delivery is communicated by telephone, and the delivery is documented on a paper delivery bill. This must then also be entered manually into a central system at a later date. This process is not only time-consuming, but also involves the risk of human error.

This makes it clear that there is still a lot to optimize in the loading and shipping process on the wheel loader. However, it is also clear that this will require some new functionalities that will make the loading process much more efficient.

What it takes for an optimized loading process on the wheel loader:

- Easy-to-use terminals, integrated directly into the wheel loader

- Overview of all relevant deliveries (“yard list”)

- Detailed information on delivery data such as material, quantity, truck, customer or delivery time

- Ensure that the right materials are loaded into the right trucks

- Automated handling of loading through simple operating procedures at the terminal

- Creation or triggering of delivery documents

- Optional:

- Online connection of the wheel loader scale

- Creation of new deliveries directly on the wheel loader

What should an optimal wheel loader solution look like?

1. integration into the shipping automation

In the first place, a shipping automation solution with standard interfaces should be integrated. This provides valid delivery data for a terminal on the wheel loader and can also receive data online from this terminal. In addition, software solutions that can be used universally, regardless of the hardware used (such as terminals or wheel loader scales), offer a decisive flexibility advantage. It is important that the system can also function temporarily offline, as a constant network connection is not always guaranteed.

2. simple operation

It is very important not to overload the wheel loader operator with too much information, but to limit the display on a wheel loader terminal integrated on the vehicle to the most necessary data. Touch operation offers the convenience of selecting the delivery and carrying out the loading process with just a few entries.

On a personal note:

One example of such a solution is the Portable Loading Module, a ready-to-use and hardware-independent standard module from Axians IAS. This module is part of the Axians VAS Yard Management System, a highly automated solution for dispatch automation that is already being used successfully in over 1,000 installations worldwide in various sectors of the building materials industry.

Simplify shipping, automate processing:

This describes the framework conditions and general requirements for shipping automation on the wheel loader.

What does a concrete implementation or workflow look like now?

Here is an overview:

At the beginning of his shift, the wheel loader operator logs on to the terminal and immediately receives a list of deliveries assigned to him or to a group of wheel loaders. This list contains detailed information such as material, quantity, delivery number, status and the assigned vehicle (license plate number).

If the vehicle to be loaded has already arrived at the loading point, the wheel loader driver can directly select the associated delivery via the vehicle license plate. If desired, he can also do this independently for the next upcoming delivery. The associated vehicle is then directed directly to the wheel loader by an online connected dispatch automation system.

From standard to customized solution:

In order to adapt the preconfigured standard solution to the customer’s specific requirements if necessary, a workshop is typically conducted together with the customer. In order to grasp the required detailed process, one should clarify the following and even more questions in the process:

- What aspects of the workflow can be made more efficient and cost-effective?

- Which of these are specifically relevant to the individual requirements of the sand and gravel industry?

- What information should be displayed or recorded at the wheel loader terminal?

- What adjustments are necessary?

- What improvements do I want to achieve?

All individual adjustments and resulting configurations and the fields to be displayed are clarified in the workshop, thus creating a solution that is optimally adapted to the customer’s requirements.

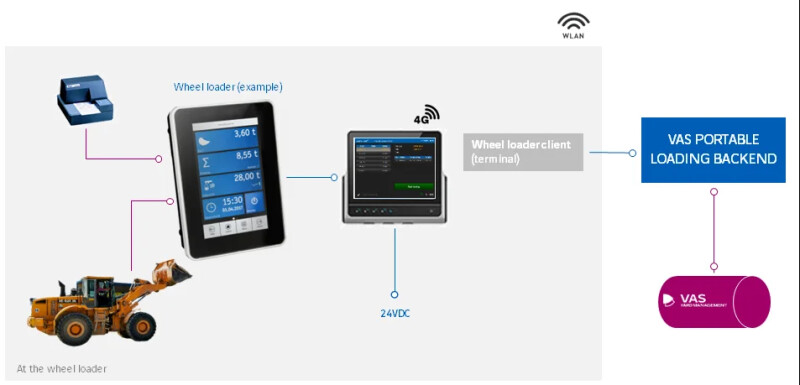

Flexible connection of a wheel loader terminal:

Many customers also demand this flexibility in terms of hardware and the connection of a wheel loader terminal. Z. For example, adaptations to different hardware can be made using appropriate adapters, and there is the optional option of supporting RFID or QR codes.

The touch terminals should be available in different sizes, depending on the requirements on the vehicle, and should already be preconfigured by the supplier. It is important to use only industrial-grade terminals that can be connected to the network either via WLAN or 5G.

If these aspects are fulfilled – as is the case with Axians’ Portable Loading Terminals – a high degree of flexibility and adaptability is guaranteed. This makes processes with the wheel loader much easier and more efficient.

Advantages through the online integration of the wheel loader:

The online integration of the wheel loader with a Portable Loading Terminal:

- Comprehensively presents all relevant delivery data at a glance.

- Enables a targeted selection of the desired delivery including all relevant details.

- Speeds up the completion of the delivery with minimal effort, optimally supported by an online connection of the wheel loader scale.

- Results in a significant minimization of manual input, making the process more agile and secure.

- Guarantees complete transparency, as the wheel loader driver as well as the weigher and the dispatch center have immediate access to the delivery data.

- Opens the possibility of paperless creation of delivery documents and noticeably reduces waiting times for the truck to be loaded.

Integrate wheel loaders online, invest in automated future:

The integration of the wheel loader into the logistics workflow is a useful extension for plant logistics in the sand and gravel sector: it speeds up processes, reduces errors, reduces manual coordination efforts, and improves customer satisfaction.

With the Portable Loading Module, Axians offers a proven and hardware-independent online solution that can be fully integrated into the VAS shipping automation solution.

You still have questions about the topic or would like to learn more about the automation of logistics workflows in sand pits and gravel plants. Do not hesitate to contact me at any time (on the link below).

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.