Cooperativa Bilanciai (Italy) - Weight and labelling of slices of cheese and sliced cheese.

Our solution:

In this context a packing department was designed specifically to meet the requirements of Coop. Produttori Latte e Fontina of Aosta.

The portioning machine can be programmed to obtain fixed weight portions or a fixed number of slices cut from a cheese for variable weight packing. A specially designed automated device conveys the slices of Fontina to the horizontal packing machine.

The packing machine can handle both BDF film and ATM film for bag packaging so that the packaging most suited to the specific requirements of the national and foreign markets can be selected.

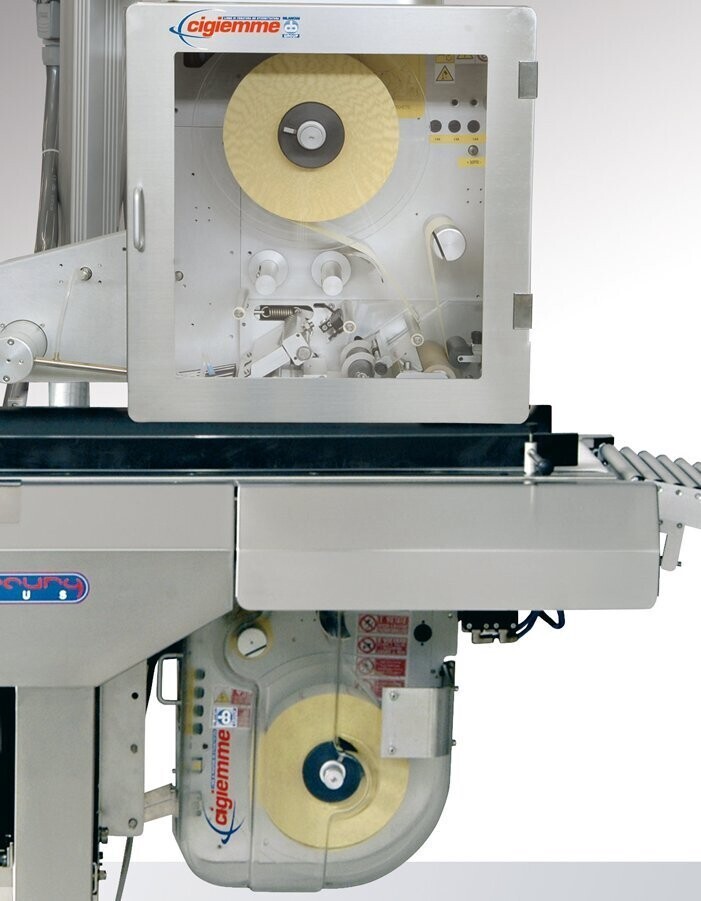

When the products packed in BDF film come out of the heat-shrink tunnel, they are conveyed to the Mercury Plus weighing, control and labelling system, which, based on the orders entered (hence depending on the customer) is able to weigh and label both variable and fixed weight products.

In the case in point, the double label printing system and application from above and below allows extremely accurately applying a brand label on the top side and a technical data label on the bottom side. This label bears the EAN barcode, all the weight indications (variable or predetermined), dates, amounts and anything else programmed in the management system for a specific customer.

An accessory printing system allows producing labels for the total pieces per box and total boxes per pallet when reaching the preset number of pieces or, more simply, when requested by the operator.

A packing list can also be printed for products to be exported indicating the weights and totals in kilograms and pounds.

The application is able to print the pallet labels with SSCC code in line with modern and efficient logistics.

The orders executed in this way, both fixed and variable weight, are recorded in the system with all the totals and the respective batches, allowing efficient accounting, invoicing and warehouse management without needing any further manual operations thus eliminating dead times, wastefulness and errors.

The system can be flexibly used to manage both large orders for fixed weight cheese portions and medium-small orders for variable and fixed weight portions with extremely fast format changes thus providing a high degree of flexibility with contained dead times.

In the case of fixed weight portions, Mercury Plus can check the package weight in accordance with the requirements of Law 690 and Pres. Decree 391 and produce a final report.

Advantages:

- Programming of fixed weight portions or a fixed number of slices cut from a cheese

- Double printing system and label application from above and below

- Brand label (top) and technical data label (bottom)

- The label bears the EAN barcode and all the weight indications

- Labels for total pieces per box and total boxes per pallet

- Printing of a packing list (kg, lb)

- Pallet labels with SSCC code

- Accounting, invoicing and warehouse management without needing any further manual operations thus eliminating dead times, wastefulness and errors

- Flexibility of system use.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.