Diverseco (Japan) - Press Release: Diverseco are excited to announce our official partnership with Konica Minolta as co-distributor and exclusive systems integrator for Mobile Industrial Robots (MiR) the revolutionary Autonomous Mobile Robots (AMRs) made in the European robotics epicentre, Odense Denmark.

Continuing our suite of partnerships with outstanding robotics companies, we’re proud to have MiR alongside our other pivotal (to the success of various industries) product offerings. MiR play an important role in the evolving industry, logistics, and manufacturing sectors by adding highly reliable, robust, and safe collaborative AMRs to organisations looking to improve their overall efficiencies through automation.

From MiR themselves:

“We are dedicated to developing user-friendly, flexible and safe robots to help companies increase the efficiency of their operations. Our autonomous robots are a new generation of advanced mobile robots which give you a rapid return on investment, often with a payback period of less than a year. These unique, collaborative robots are now used by manufacturers in a wide range of industries and healthcare sectors to automate their in-house transportation.”

Within the field of AMRs, MiR were among the heralds of this technology and have been perfecting their suite of AMRs since, continuing to add value to their prospective and existing clients by expanding their growing range of product offerings with new technology.

These systems are designed to optimise workflows, increase productivity, and reduce costs. They are 100% automated, can easily engage with human operators in collaborative harmony, and are easy to integrate into any time of existing factory layout. How do these systems work? Watch the short video below to find out.

MiR History:

The foundation of Mobile Industrial Robots was laid in 2011 when MiR’s founder, Niels Jul Jacobsen, created the first example of what would one day become a MiR robot using his son’s LEGO bricks.

Officially founded in May of 2013 in Odense, Denmark with the idea of optimizing logistics in the global industry, MiR would see two years of groundbreaking research and development before their first AMR, the MiR100 , would be commercialised.

In 2015 the first MiR100 robots were produced and sold and from here the company quickly gathered speed.

In 2016 the MiRHook was launched, a regional office in New York was opened and MiR moved into a new HQ in Odense, Denmark.

In the following years MiR expanded with new regional offices and new products to improve internal logistics in a wide range of industries. Over time, the company has won multiple internationally renowned awards and in 2020 MiR launched the highly adaptable and flexible MiR250.

Today there are seven offices around the world, more than 220 employees and 167 distributors in 48 countries!

MiR Applications:

Automotive:

Robots have been prevalent in the automotive industry for almost 60 years now, but the use of autonomous mobile robots (AMRs) is still relatively new. Unlike automated guided robots (AGVs), autonomous mobile robots can move out of the way of obstacles independently, are easy to set up and don’t require fixed routes. This makes them safer, smarter and more flexible than AGVs.

Electronics:

Today’s consumers not only want the latest models as quickly as possible, but also more durable, high quality and sustainable goods.

This is putting huge demands on the electronics manufacturing industry. Couple this with omni-channel ordering, tracking and returning, an aggressive reviewing culture and some hard-to-ignore tariffs, and you get an electronics industry that can do little else but be as responsive as possible while keeping costs low.

To stand a chance of competing, manufacturers and suppliers need to automate processes for a flexible, productive and high value supply chain. While automation and robotics are no stranger to the electronics industry, there is still room to go further with a new generation of innovative technology.

Fast-Moving Consumer Goods:

As market demands continue to change, so must the supply chain. In fact, today’s factory floor is vitally different to the one of even twenty years ago, with high-speed conveyors, cobot arms and other automation technology that complete processes faster and more accurately than manual labor.

And while large internationals within FMCG such as P&G, CocaCola & Unilever (to name a few) have seen success from their automation practices, businesses must keep innovating in order to compete better.

Logistics:

In recent years, the logistics industry has expanded at an unprecedented rate, thanks to increasing expectations from e-commerce consumers. However, finding workers who are willing or available to take on a job in logistics is proving to be a serious threat. And the problem doesn’t just apply to jobs related to manual work on the shop floor, but also at a more academic or skilled level.

To mitigate the labor shortage logistics companies have no choice but to boost productivity of the existing workforce by investing in more autonomous technology, like autonomous mobile robots (AMRs).

Life Science:

The life science industry – defined as pharmaceuticals, biotechnology, med tech and nutraceuticals – is expected to reach sales of 1.9trillion USD by 2022. While it’s positive for the industry to have a growth rate that defies the continued price pressure, individual companies will see increased competition. In fact, given the continuously evolving trends in life science, even legacy companies run the risk of being outcompeted.

In order to stay ahead of the pack, and take advantage of the growing space, brands must take a leaf from the biotech players and become innovation first movers. Cutting edge technology like Autonomous mobile robots (AMRs) will help businesses compete better, by increasing worker safety, productivity and flexibility, all with a fast ROI.

We’re excited about looking to the future of our ability to add value to existing clients, as well as attract new clients with our well-rounded product and solution portfolio with the addition of MiR.

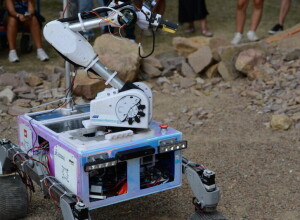

Picture 2 Caption:

The MiR200 with ancillary attachments.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.