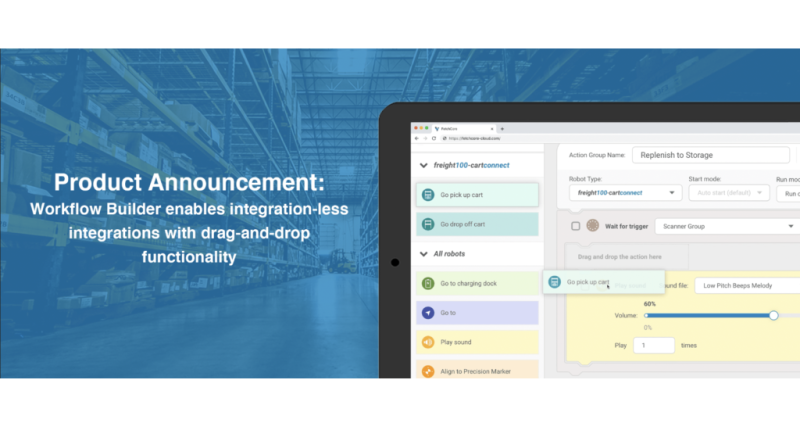

Fetch Robotics, Inc. (United States) - Press Release: After months of extensive customer research to help simplify complex automation workflows in factories, fulfillment centers and distribution centers, today we celebrate the launch of Workflow Builder. Workflow Builder is our new drag and drop development toolkit directly within FetchCore, our cloud-based software platform that enables on demand automation. Workflow Builder lets customers implement automation workflows on-demand without the need for third-party resources. Our team has worked tirelessly with customers to understand challenges in implementing automation workflows that can show value immediately without going having to go through the hassle of WMS integration – integration work is costly, disruptive, and there’s basically no guarantee that the automation workflows will meet ROI expectations. Without an easy way to test workflows until they’re perfect, facilities feel chained by integration and become unable to innovate.

When traditional automation solutions are in place, they’re difficult and expensive to change:

Traditional automation solutions typically require a third party integrator to scope, design, install, and maintain the solution, especially fixed automation like conveyors, ASRSs, etc. Traditional AMR solutions often require facilities to be modified with QR codes, fiducials or tape stuck to the floor, and mandatory integration with other systems, such as a WMS. Once the costly integration was done, the project team would have to cross their fingers and hope that the workflow delivers the KPIs and ROI initially projected. And then it could be too late as once these solutions are in place, they’re difficult and expensive to change.

Based on this feedback, we designed Workflow Builder to be incredibly easy to use, accessible from within our cloud-based platform, and with no WMS required, allowing customers to have integration-less integrations in their facilities within days. This allows customers to see ROI almost immediately, especially when purchased with a RaaS model. This way, they can keep improving the workflows until they’re happy, and then integrate if desired. If the business needs change, or if it’s no longer peak season, or if the ROI isn’t as projected, they can easily adjust the workflow or redeploy a different workflow. Rinse and repeat as needed.

It’s insanely simple. We mean it:

Workflow Builder is a new approach to an industry with customers that can be risk-averse. While other solutions solve for a specific application, we’ve built our platform to be incredibly simple, scalable, and flexible, allowing our customers to take back the control and innovate their businesses themselves while gaining full confidence in their decisions.

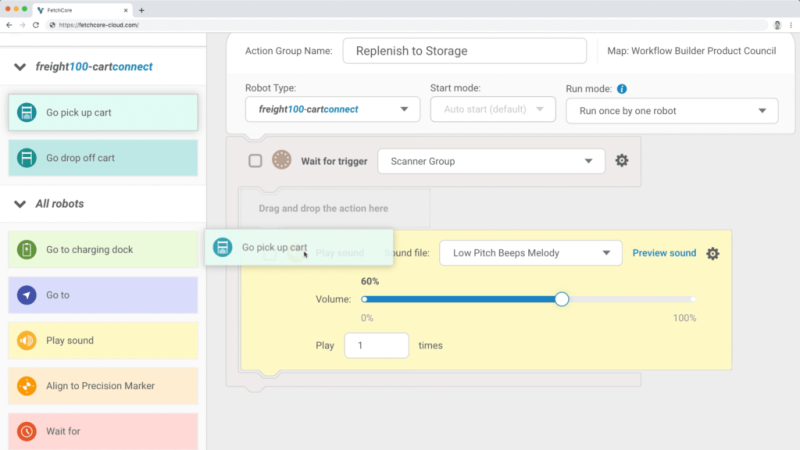

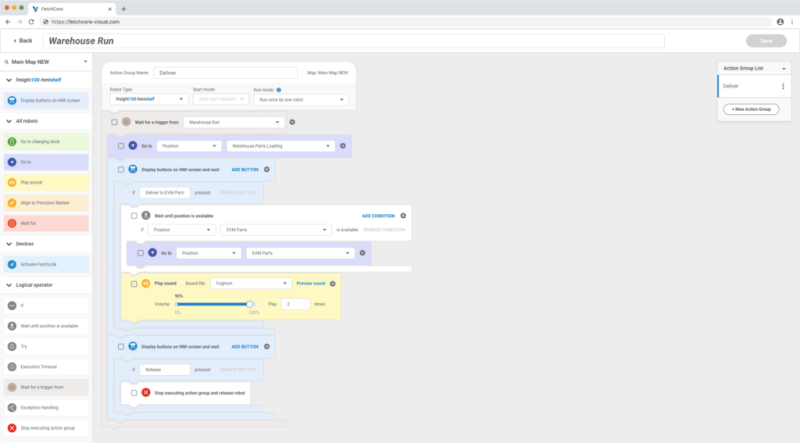

When we say simple, we mean it, in more ways than one. Within 3 easy steps – drive the robot around the facility to map it, lay out the workflows, and drop-in device triggers all through FetchCore – you have now implemented AMRs. Additionally, Workflow Builder is so simple, even kids can learn to do it. Workflow Builder is built on Blockly, the visual interface that has been used to teach kids how to code by dragging visual blocks to create commands. Like Blockly, Workflow Builder uses graphical blocks to represent code, or in this case, workflows, within our cloud-based platform. Each Fetch AMR has multiple choices of blocks specific to that robot. For example, a block for a cart movement workflow can be different from an available block for a workflow that moves totes autonomously between conveyors and ASRSs. Say that you’d like your AMR to pick up and drop off a cart from a storage area to picking, you will simply drag and drop the corresponding blocks and determine their locations and off the robots go. We’ve built Workflow Builder to be incredibly simple to make sure that anyone can do it. Contrary to what you may believe, you don’t need a robot engineer, custom coding, or a full IT team to implement material handling in your facility.

With Workflow Builder, we empower our customers to take full control over their business, instead of failing to innovate because they feel immobilized by millions of dollars of outside integration work. You don’t need an IT team, new infrastructure, or outside integrators to create a dynamic business. So if you were worried that your facility isn’t ready for AMRs right now, trust us, it is.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.