Minebea Intec (Kenya) - Press Release: Maximum product safety and efficiency.

Minebea Intec, a global pioneer in industrial weighing and inspection technologies, will be exhibiting at ProPak 2024 in collaboration with respected African partner Statpak Industries. ProPak is East Africa's leading exhibition and conference for the packaging, printing, food and plastics industries. From 12 to 14 March at The Sarit Exhibition Centre in Nairobi, Kenya, visitors will be able to see Minebea Intec's product portfolio for checkweighing, foreign body detection like metal detection, static and process weighing and truck weighing amongst others. The company is also actively seeking additional service and sales partners in Africa. Minebea Intec looks forward to welcoming visitors to Stand A4.

Interested visitors can experience Minebea Intec's leading weighing and inspection solutions at ProPak in action. These technologies greatly increase the efficiency and product safety of manufacturing companies. One highlight on the stand will be the checkweigher Econus®, which is suitable for a wide range of inspection applications such as completeness checks, quality control, classification or optimisation of filling and dosing processes. Its rugged and sturdy mechanical construction and sufficiently heavy weight ensure accurate and repeatable weighing results even at the highest speeds.

For the detection and rejection of metal contaminated products, Minebea Intec offers high-precision metal detectors. Manufacturers who opt for metal detection benefit in many ways. First and foremost is the assurance of product quality and consumer protection. Contaminated products can lead to expensive recalls and brand damage. Minebea Intec offers two metal detection systems for the food industry, Vistus® and Mitus®. Mitus® was only launched last year and has an even higher detection sensitivity than Vistus®. But whether you choose the Mitus® or Vistus® metal detector: Both solutions can be integrated one-to-one with our conveyor, free-fall or pipeline systems.

X-ray inspection: delivering safety, integrity and quality

X-ray inspection systems not only detect products contaminated with metal, but also with glass, rubber, stones, plastic parts or bone fragments. They can also perform in-line quality checks such as weight determination, component counting, detection of missing or defective products, fill level checks and closure integrity checks. Minebea Intec offers a wide range of X-ray systems for the inspection of packaged products. Typical applications include cartons, boxes, bags, trays and portion packs containing a variety of dry or liquid food products.

Industrial scales: versatile solutions for precise production processes

Whether for checkweighing, completeness verification, classification, sorting and counting by weight or dosing: the industrial scales of Minebea Intec can be integrated at almost all points of the production process. The static industrial weighing solutions include table and floor scales, flat-bed scales, pallet scales and weighing platforms.

Minebea Intec has both highly sensitive industrial scales for measurements of 0.001 g and very robust weighing systems with which you can weigh several tonnes. Minebea Intec will be exhibiting the industrial scale Puro® and the bench scale Miras® at ProPak. The scales in the Puro® series have been developed for a wide range of weighing requirements. Whether weighing, counting or quality control – all Puro® scales are characterised by speed and precision. With their robust design and user-friendly applications, Puro® scales have proven themselves in all areas of industrial weighing.

The Miras® bench scale fulfils a variety of tasks solidly and reliably – from piece counting to content control. All scales of the series consist of a painted frame construction with a stainless steel load plate. The indicator is mounted on the stand supplied as standard.

Load cells and weighing electronics for most precise and durable truck, silo and vessel weighing applications

Whether storage tank or external silo, batching vessel, mixer or reactor – Minebea Intec offers tailor-made equipment for almost every hopper scale: digital and analogue load cells and weighing modules, innovative weighing electronics, reliable cable junction boxes and installation kits for a wide range of application requirements.

The product portfolio includes a wide range of weighing solutions for checking fill levels as well as for dosing and filling. At one end of the spectrum, these include cost-effective solutions for inventory control, where a weighing system accuracy of a few per cent is perfectly adequate. At the other end, Minebea Intec offers high-precision solutions that enable the exact dosing of a small component into a large dosing container – even during a mixing or heating process.

At ProPak, Minebea Intec will be presenting the truck scale load cell PR 6221 and the weighing transmitter Link E. The load cell PR6221 guarantees precise results, durability and reduces costs in the medium term. Their outstanding precision and durability reduce service and calibration costs and help to minimise downtime. In order to be able to use the weight values efficiently, the signals from the analogue load cells must be determined and passed on to the control system. This is where weighing transmitters such as the Link E come in. As the first weighing transmitter for analogue strain gauge load cells, the Link E has a high-contrast touch display on which all information and settings are visible and easy to find at all times. It can be configured without additional software via a standard web browser. "Smart Calibration" enables adjustment completely without weights. This minimises installation and access times.

Expanding market access with local cooperation partners

Minebea Intec's mission is to provide industrial customers around the world, including the African market, with high quality weighing and inspection solutions, from entry-level to premium models. In order to achieve this goal in the best possible way, the company, which is headquartered in Hamburg, Germany, is looking for additional cooperation partners in Africa who can market and service the entire portfolio of inspection machines, industrial scales and load cells. “We've been following the great developments in Africa for many years. It is time for us to focus more on this very interesting and high potential market. That is why we are participating in ProPak this year and want to establish new business relationships with local companies that are interested in joining us on our journey to provide the best possible weighing and inspection solution for industrial producers in Africa," says Willy-Sebastian Metzger, Director of Business Development and MarCom at Minebea Intec.

Minebea Intec's global network currently consists of over 200 qualified partners in 70 countries. The company attaches great importance to its network of dealers and representatives. For this reason a dedicated program is running that is focussing on the support and development of the individual partner company based on its needs and opportunities, e.g. by providing regular product trainings, marketing support or special conditions to tackle the local market in the best possible way. “Our partner programme helps to create strong sales and service organisations with a clear focus on providing customers with the optimal industrial weighing and inspection solution based on their actual needs and requirements," concludes Willy-Sebastian Metzger.

Minebea Intec at the ProPak 2024

Visitors are cordially invited to experience Minebea Intec's technologies in action, find out about innovations and learn more in direct dialogue with the experts. The Minebea Intec team will also be happy to answer any questions about the Partner Program. Visit Minebea Intec on stand number A4 and experience the future of industrial weighing and inspection technologies up close.

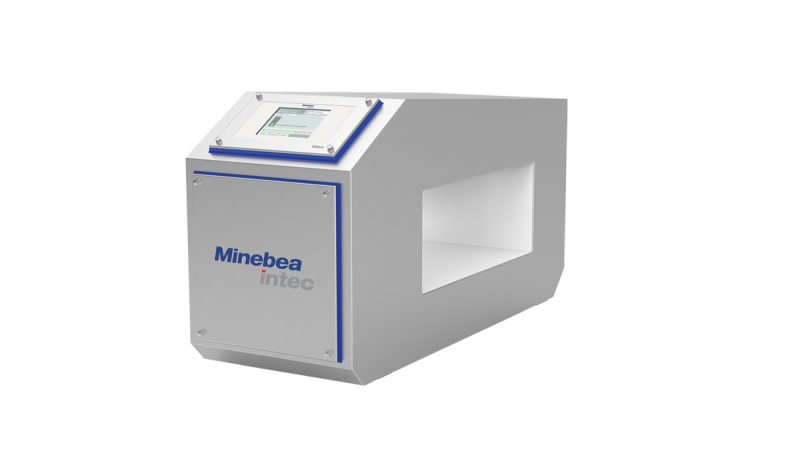

Image 1 Caption:

The Mitus® metal detector utilises innovative MiWave technology to detect even the smallest metallic foreign objects with great product effect.

Image 2 Caption:

The Econus® checkweigher is the ideal economical solution for numerous weighing applications, completeness checks and the optimisation of filling processes.

Image 3 Caption:

The Dylight X-ray inspection system guarantees maximum safety for your packaged food.

Image 4 Caption:

Weight transmitter Link E – with intuitive touch display.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.