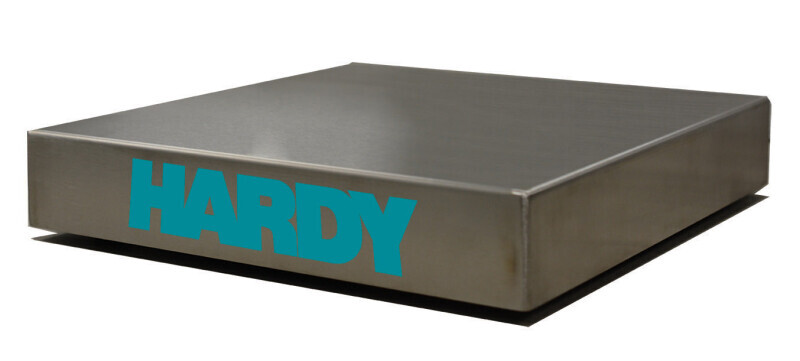

Hardy Process Solutions (United States) - Press Release: Hardy Process Solutions has announced a new new line of bench scales that are easy to clean, low-profile and all stainless-steel construction. The HIBSX series offers simplicity and robust performance for light duty industrial weighing applications.

To ensure durability in industrial applications, Hardy has performed corner, overload and cycle testing to over 8 million cycles. The HISBX series is ideal for manual checkweighing, piece portioning, counting, and adding minor ingredients to a process or a batch.

With an optimized internal 'X' design, the scales reduce the time required to sanitize them while offering one of the lowest profiles in the industry at just 2.02 to 2.95 inches (51.3 to 75 mm adjustable). Hardy HIBSX Bench Scales come with RoHS compliant 304 Stainless steel hardware, frames and platters. Users may choose between stainless steel hermetically sealed, IP68/69K, C2® load cells or aluminum, environmentally sealed, IP67 C2® load cells, depending on their application.

Made in the USA, all Hardy HIBSX Bench Scales come standard in the most popular 12”x12” size, ranging in capacity from 10 lbs – 165 lbs (5 kg to 75 kg). They are designed to meet a combination of customer requirements, including form factor, washdown, and use in hazardous areas.

“Hardy has built its C2® weight-free calibration technology into every scale, delivering the lowest total cost of ownership on the market,” said Jeff Moen, product manager. “C2 calibration saves time during commissioning and replacement, removes extra personnel from processing areas, and keeps your manufacturing process cleaner by eliminating the need for potentially contaminated test weights.”

With hazardous FM approval, the HIBSX with the stainless steel load cell is built for washdown applications and hazardous environments. With an IP67 aluminum load cell, the HIBSX is designed for use in dry and dusty hazardous environments. Each load cell has a +/- 0.02% accuracy specification.

About Hardy Process Solutions (A Roper Technologies Company):

Hardy Process Solutions has established itself as an industry leader in the weighing automation world by providing highly accurate precision measurements, while seamlessly integrating process weight signals into a Rockwell plant control system. At Hardy, we believe that industrial weighing solutions should be EASY to engineer and operate. We believe that simplicity delivers the LOWEST TOTAL COST to own. That’s why our solutions are EASIER to install, integrate, commission, diagnose and maintain in all four areas of the supply chain.

- STOCK - accurate weight and level measurement/monitoring

- MAKE - adaptable weight & rate material feed measurement/control

- PACK - for robust rate & weight feed measurement/control

- SHIP - off-the-shelf static and dynamic check weighing solutions

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.