Owens Design has carved out a unique niche as a designer and builder of complex manufacturing equipment. Based in Fremont, Calif., the OEM provides equipment design and manufacturing services to machine builders in the semiconductor, solar, data storage and other emerging technology industries. The company's services include complex electromechanical design, motion control and project management to create automated machinery and systems.

Remaining competitive and keeping customers happy hinges on the company's ability to deliver machines that are sophisticated, reliable, versatile and user friendly. To meet these demands, the company relies on its specialized engineering expertise, finely-tuned project management skills and cutting-edge automation and control technology.

A solar start-up company contacted Owens Design about building an automated process assembly tool for its innovative photovoltaic (PV) cell manufacturing operation. The tool needed to accurately punch a pattern of holes into a plastic interconnect material at high speed, cut it to length, and then place the cell components into carrier trays for the next operation. The machine would need to employ an advanced vision system at the input and output to inspect for surface and dimensional defects and provide positional feedback for the robotics.

The company had demonstrated the process with manual tools, but needed a fully automated system that could meet its high throughput demands. Because the subassembly tool was designed to support a much larger solar cell manufacturing operation, meeting the end user's aggressive delivery schedule was crucial.

Adding to the challenge was the need to integrate a variety of third-party components into the tool design, including stepper motors, pneumatic manifolds, RFID tag readers and smart cameras.

Owens Design chose the Rockwell Automation Integrated Architecture™ and EtherNet/IP™ as the controls foundation for the assembly tool. EtherNet/IP uses standard unmodified Ethernet to manage real-time control and information flow from the machine-level to the IT enterprise.

"The use of an EtherNet/IP network to connect third-party components would help us streamline assembly, reduce wiring costs and simplify integration of our tool into the customer's manufacturing operation," says Doug Putnam-Pite, director of software development, Owens Design.

It also was important to employ advanced servo motion control technology that would give the tool the speed, accuracy and versatility required in this demanding manufacturing operation.

Integrated Motion Eases Programming:

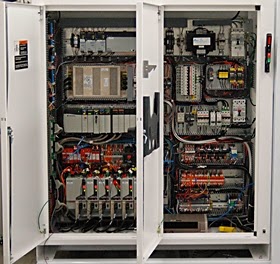

To achieve the precise machine movements and positioning, Owens Design implemented an Allen-Bradley® Kinetix® Integrated Motion solution from Rockwell Automation, featuring an Allen-Bradley ControlLogix® programmable automation controller (PAC) and Kinetix 6000 multi-axis servo drives. Together, they're responsible for coordinating and controlling all major functions of the assembly tool, including cutting and hole punching tasks, guiding and feeding of the interconnect material, and placement of the processed components into the carrier trays.

The solar company working with Owens Design needed a control system with high performance and ease of connectivity for its automated process assembly tool. (Click to enlarge)

The Rockwell Automation Integrated Architecture provided an integrated platform to create motion and machine control using a single programming environment. An extensive motion instruction set is embedded in the ControlLogix controller and is programmed using the Rockwell Software RSLogix™ 5000 programming software. This allows engineers to configure motion and sequential control in a single package, resulting in faster application development and lower overall cost.

To configure the motion system, engineers simply select the motors and drives the machine will use and all parameters and encoder information are generated automatically. Once the basic movement commands are programmed, engineers can duplicate them for other axes in the program, dropping them in where appropriate.

The Kinetix servo drives deliver the precise positioning needed to accurately guide the interconnect material as the tool punches, cuts and places the processed material into the carrier trays at high speed.

An important element of the new control system is its ability to use EtherNet/IP to connect to third-party components. Multiple discrete wires were replaced by a single EtherNet/IP cable to integrate an intelligent component such as a vision camera or RFID tag into the control system.

"The ability to distribute components throughout the tool proved to be a huge timesaver," says Bob Fung, vice president of engineering. "We simply placed the components where they were needed along the length of the tool. This dramatically reduced our wiring cost and helped speed installation and commissioning."

Two Allen-Bradley SmartGuard™ 600 controllers, linked via EtherNet/IP, perform a variety of safety monitoring and control functions and seamlessly link to other machine control devices. An Allen-Bradley Stratix 8300™ managed switch helps ensure proper network segmentation, allowing the end user to integrate multiple cell zones across the plant while helping to achieve secure integration at the enterprise level.

Precision and High Performance:

"During the design phase, the Rockwell Automation programming environment allowed us to divide the project into separate modules and have people work on them independently, which is not possible with some other systems," Putnam-Pite explains. "This helped speed system engineering and configuration."

Ease of integration also proved to be an important advantage of the Integrated Architecture system. Using an EtherNet/IP design allowed engineers to connect a variety of low cost, off-the-shelf components into the system, many of which included add-on profiles to RSLogix 5000. This eliminated the need for designers to write custom drivers for each device, helping Owens Design reduce its engineering time by 30%.

By leveraging EtherNet/IP, technicians only needed to connect a single communications cable and power line between the main cabinet and remote I/O modules. By placing the I/O close to the individual devices, engineers were able to eliminate hundreds of feet of cable and much of the repetitive hardwiring, helping to reduce installation time by approximately 40%.

The information-enabled control system also brings benefits to Owens' customers. Because the subassembly tool is part of a larger manufacturing operation, it's critical that operators have quick and easy access to diagnostic data, such as fault identification. With EtherNet/IP, technicians can isolate problems to an individual section of the machine.

Detailed drive and motor status information is easily accessible via a touch-screen human-machine interface (HMI), allowing operators to respond to impending problems and help minimize unplanned downtime.

"The plug-and-play connectivity of the Rockwell Automation Integrated Architecture proved to be a huge advantage for us, as well as for our customer," says Fung.

"It gave us the design speed and efficiency we needed to meet the customer's tight delivery timeframe, along with the ability to take advantage of the wide selection of off-the-shelf components," he adds. "This allowed us to deploy the best of available technologies and deliver a robust, reliable and more tightly integrated system."

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.