Coperion (China) - Complete Automatic Compounding Lines From a Single Source.

Coperion China was awarded three Smart Compounding Lines from Nanjing Julong Science & Technology Co., Ltd., for the production of PP (polypropylene) and PA (polyamide). All three lines have been successfully installed and are in full operation. Coperion’s Smart Compounding Lines are pre-configured turnkey solutions from a single source. Developed in best-practice design, the compounding lines are tailored with focus for the Asian market.

Coperion’s scope of the Nanjing Julong project included the engineering and design of the three lines as well as their installation supervision and commissioning. Coperion delivered the entire solution from raw material handling receiving to the handling of finished goods, including three ZSK 70 Mc18 twin screw extruders assembled locally at Coperion Nanjing, strand pelletizers from Coperion Pelletizing Technology, a silo washing system and the Distributed Control System (DCS).

Up to now, the new Smart Compounding Lines are running reliably at the highest throughput rates and Coperion will further support Nanjing Julong as a service partner. Coperion will provide the site and spare parts service for the entire plant.

High Level of Automation for Maximum Plant Efficiency:

Together with Julong, Coperion’s engineering teams in Shanghai and Nanjing have planned, developed and designed the entire factory from layout to commissioning. Based on the extensive know-how collected from more than 150 installed compounding lines, one of Coperion’s main focuses was on user-friendly plant design by improving the working conditions for the operators at every step of production. The result comprises a high level of automation and digitalization of Julong’s plants. Central functions are performed by the DCS Control System which has an interface and signal exchange with Julong’s Manufacturing Execution System and supports and improves Julong’s automated processes from order handling to manufacturing and thus increases the efficiency of the entire production.

ZSK Twin Screw Extruders Form the Heart of the Compounding Lines:

The three Smart Compounding Lines are each equipped with a ZSK 70 Mc18 twin screw extruder with a screw diameter of 70 mm and a specific torque of 18 Nm/cm³. ZSK extruders are ideal for processing products with a high torque requirement, such as PP and PA. The ZSK 70 Mc18 twin screw extruders are locally assembled at Coperion’s manufacturing site in Nanjing, China. Chinese customers benefit from local added value, transport, and tax savings as well as from shorter delivery times. Even the after-sales services are customized to local parts and needs.

Coperion’s SP Treasure Strand Pelletizers Produce High Quality Pellets:

Julong’s three Smart Compounding Lines are equipped with Coperion’s SP 320 treasure strand pelletizers. This strand pelletizer series was developed through close cooperation between Coperion Pelletizing Technology, Offenbach, Germany and Coperion Nanjing. Coperion Pelletizing Technology is responsible for the design and manufactures the cutting chamber. The remaining pelletizer assembly is manufactured locally in Nanjing. The SP 320 treasure strand pelletizer is ideally suited for processing of highly abrasive strengthened products. It has a working width of 320 mm and can process up to 88 strands at throughput rates of up to 2,500 kg/h. Key design features of the SP treasure pelletizer include high throughput rates, excellent accessibility and ease of cleaning.

Strategy Results in Fast Return on Investment:

The successful operation of Julong’s three Smart Compounding Lines is proof of Coperion's many years of experience in the realization of turnkey solutions. Coperion exclusively uses high-quality, tried-and-tested components within Smart Compounding Lines – a strategy which results in high process safety and user-friendly system design with consistently good product characteristics and a long service life. Considering this first-class, reliable technology along with optimum interaction of all process steps and the high throughput rates of the three compounding lines, the return on investment will quickly be achieved. In addition, Julong will continue to benefit from available local spare parts, avoiding time-consuming and expensive import procedures.

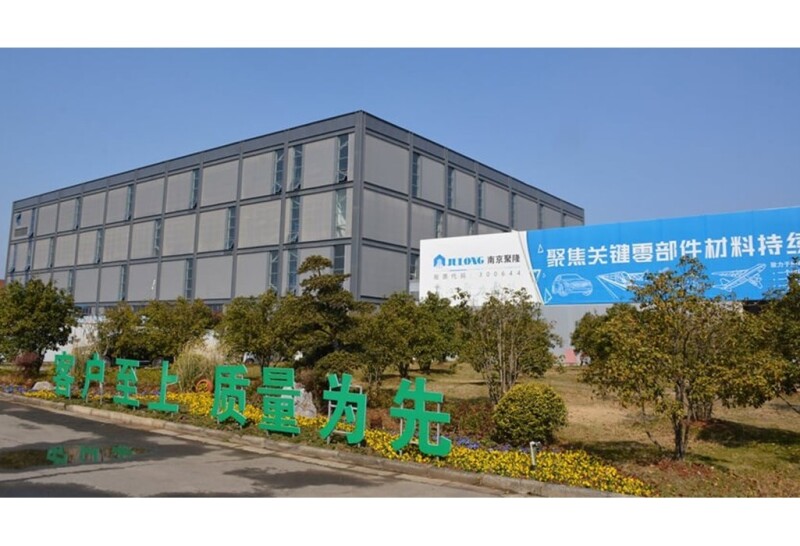

Picture 1 Caption:

Coperion China was awarded three Smart Compounding Lines from Nanjing Julong Science & Technology Co., Ltd., which have been successfully installed and are in full operation.

Picture 2 Caption:

The ZSK 70 Mc¹⁸ twin screw extruder is assembled locally at Coperion Nanjing and plays a key role in the successful operation of the Smart Compounding Lines at Nanjing Julong Science & Technology.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.