Thermals, Enclosures, and Dust: Designing Rugged Edge Nodes

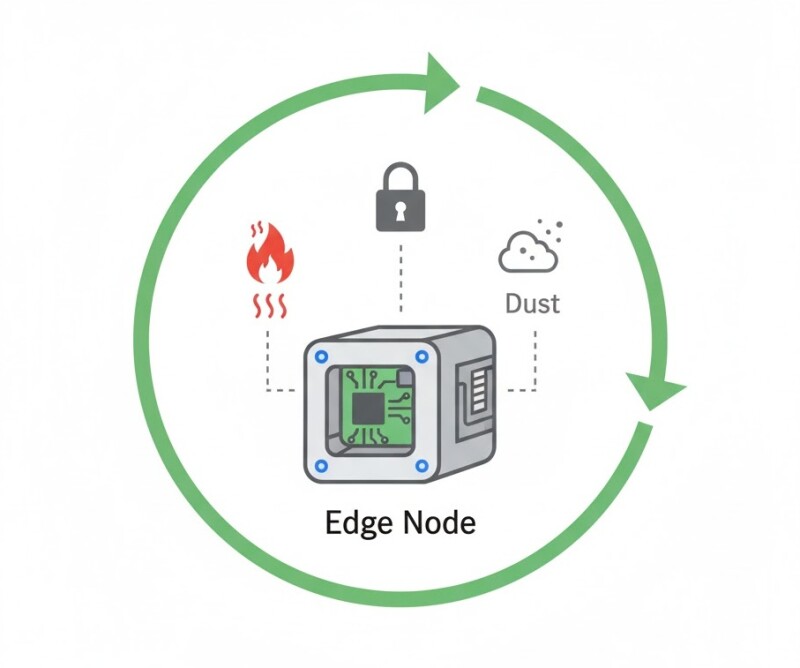

Deploying AI at the edge means running compute in the harshest conditions: vibration, heat, and airborne particulates. A successful design starts with thermal engineering and ingress protection, not software.

Thermal Design Basics

- Maintain junction temperatures below 85 °C for sustained performance.

- Prefer passive cooling with finned heatsinks for reliability.

- Use heat pipes or vapor chambers when airflow is restricted.

Enclosure Protection

- Minimum IP54 for dust and splashes; IP65+ for washdown zones.

- Corrosion-resistant materials (aluminum, powder-coated steel).

- EMI shielding to avoid interference with PLCs and RF sensors.

Dust and Debris Control

Fanless designs prevent ingress but trap heat; filtered fans require maintenance. Many integrators adopt positive-pressure cooling — pushing filtered air outward to block dust intake.

Example Configuration

A Jetson Orin-based vision node in a stamping plant was enclosed in an IP65 box with heat pipe cooling. Operating temperature dropped by 22 °C compared to open mounting.

Related Articles

- Jetson Orin vs Intel iGPU vs AMD: A 2025 Buyer’s Guide

- Real-Time Considerations: Determinism Next to AI

- Lifecycle and Spares: Designing for 5-Year Support

Conclusion

Edge AI systems live in hostile environments. A well-designed thermal and enclosure strategy ensures that intelligence at the edge stays reliable — even under industrial stress.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.