Automation Inside Awards 2018

Here are the Automation Inside Awards 2018 WINNERS. Congratulations!

First place

HBK - Hottinger Brüel & Kjaer

In 2019, industry market leaders HBM and Brüel & Kjær joined forces as Hottinger Brüel & Kjaer to form the world’s foremost...

Second place

Utilcell

UTILCELL is a manufacturer of Load Cells, Mechanical Accessories and Weighing Electronics. Since our beginnings, 40 years ago, we have been on...

Third place

Minebea Intec

Minebea Intec is a leading manufacturer of industrial weighing and inspection technologies. With its headquarters in Hamburg, Germany, for around 150...

.jpg)

Minebea Intec Weight Controller Maxxis 5

The freely programmable weight controller Maxxis 5 is designed for applications as diverse as Phase, Batching, Filling, IBC, Counting and Truck Weighing. Extensive connectivity options and compatibility with all analogue load cells and the digital Pendeo® load cells as well as platform scales and many more weighing solutions.

- Connection of up to four scales

- 5.7" large colour display with multilingual interface and integrated help function for intuitive operation

- Multiple interface possibilities: Ethernet TCP/IP, Modbus TCP, Profibus DP, DeviceNet, Profinet, Ethernet/IP and USB

- Equipped with an internal web server, the Maxxis 5 can be configured and controlled via any standard web browser

- Automatic backup function saving data to SD cards for full transparency and traceability

NexCOBOT MiniBOT-7R Educational Robot Tool Kit

Based on EtherCAT communication standard, NexCOBOT MiniBOT-7R provides an expandable distributed control system. It is also a good material for EtherCAT-related training and the naked frame allows students to easily learn the structure of an industrial robot. MiniBOT-7R includes a utility tool to directly operate the robot. Robotic control API is also provided in Windows platform so that users can leverage its openness to develop any kind of robot applications.

Main Features:

- EtherCAT Communication

- Industrial Robot Design

- Open Development Environment, highly compatible with 3rd party deep learning solution

- Customizable for your own enclosure for Robot Arm by 3D Printing

- Designed with an effective payload of 1 kg.

- Provides Robotic Control API

- The electric control box is provided with 15 DI points and 16 DO points.

- Runs on NexARC runtime (Robot control runtime) and NexMotion Studio (Configuration Utility).

- Uses Motor with Tuque control

- Operation Range: 576.5mm (Maximum): J1: ±167° J2: ±110° J3: ±167° J4: ±175° J5: ±167° J6: ±85° J7: ±180°

- Complete Robotics Curriculum and Training Material Provided

- Safety : 1 x EMG Stop on teach pendant, 1 x EMG Stop on external I/O

Minebea Intec Load Cell Inteco® with converter Connexx®

Analogue and digital: the new load cell Inteco comes with an upgrade

The load cell Inteco, a new, innovative enhancement to its successful predecessor, the PR 6201 load cell, provides customers from various industries with a significantly extended range of possibilities – from simple fill quantity control to high-precision weighing of even the heaviest silos and containers.

- The analogue output signal of 2 mV/V sets a standard on the market and ensures flexibility when selecting weighing electronics

- Higher load levels of up to 75 t allow even the heaviest silos and containers to be weighed safely and ensures a more economic weighing solution, for example with three load cells instead of four

- Expanded accuracy classes and increased precision are documented by C6 approval

- A new type of stainless steel makes the load cell Inteco resistant to corrosion and prolongs the service life in challenging environments, such as the chemical industry

Analogue or digital? The load cell Inteco can do both

- Fitted with the converter Connexx, the Inteco can be installed easily and economically without the need for a cable junction box

- Fast signalling times ensure reliable, precise dosing processes and optimal transparency. Weight values can also be generated individually – per load cell – meaning that defective load cells can easily be identified and replaced

- The standard interface CANopen ensures straightforward commissioning and calibration via PC. It is also possible to use cables up to 200 m in length

UTILCELL SWIFT - Weighing Indicator and High Speed Transmitter

UTILCELL (Spain) - The SWIFT is a Weighing Indicator and High-speed Transmitter, especially indicated for Process Weighing & Machinery, in both static and dynamic applications. Now is available with the specific Dosing and Filling Application (APP) turns easy the control of the dosing processes of filling and dosing of materials such as liquid, powder or granules.

Due to its design as well as the many possibilities of data transmission, smart weighing functions, digital inputs and outputs, it is ideal for connection to PLC, PC and remote systems making easy the integration in automated systems. We highlight the ease of commissioning and the reliability improvement and speed of the process without the need to add external control systems.

Its main characteristics are:

- High-speed reading: 2400 measures per second.

- High resolution: 24-bit ADC with 16,000,000 internal divisions and 100,000 external divisions.

- Legal-for-trade IPFNA Legal Weighing Measurement Certification (Non-Automatic Weighing Instruments Weighing Indicator).

- Calibration by masses or in mV/V.

- Calibration sealing by software or mechanically.

- Configuration and calibration by keyboard or computer.

- Selectable digital filters.

- Power up to 8 load cells (350 W) or up to 16 load cells (700 Ω).

- RS-232 & RS-485 communication (Modbus RTU & ASCII).

- PROFIBUS, PROFINET & ETHERNET/IP communication.

- Analogue output configurable at 0-5 V, 0-10 V, 0-20 mA & 4-20 mA, with galvanic isolation.

- 3 Digital opto-isolated inputs with status LED.

- 3 Digital outputs to relay with status LED.

- DIN Rail and Panel mounting versions.

Other regular applications:

- Filling and dosing machines.

- Weighing and level measurement in tanks & silos.

- Check-weigher scales.

- Animal weighing scales.

- Test machinery.

- High-speed dynamic sorting scales.

- Multi-head scales.

- PC/PLC weight transmission.

- Multiple weight indicators in the same bus.

No nominations to this category

Minebea Intec Software ProRecipe XT®

ProRecipe XT® is the intuitive recipe management system for all manual and semi-automatic recipe processes.

The innovative software guarantees complete and controlled product safety in the food, pharma and cosmetic industries as well as a wide range of other industries.

- Intuitive monitoring and management of recipe processes

- Flexible integration into production systems

- Guaranteed traceable product quality

- Meets the validation requirements of the pharma industry

NexCOBOT NET 300 Advanced Robot Controller

NexCOBOT NET 300-ARC is an intelligent PC-based advanced robotic controller for robot automation. It integrates NexCOBOT's general robotic control software, NexGRC, and Actin runtime kernel from advanced software and robotic systems developer Energid Technologies, to perform real-time motion control and support redundant robots, such as articulated 7-axis robots, or provide co-robot functions to standard articulated 6-axis robots.

Specifications:

Pre-Installed Software Package

- Operating system: Windows Embedded Standard 7

- NexARC Runtime

- NexMotion Studio

NexARC Runtime

- Supported robot type: Articulated 6- & 7-Axis

- Robot control command: PTP/linear/3D arc

- Robot blending motion: Aborting/buffered/ blending

- Ramp profile: T curve/S curve

- Optimized path planning: Joint limit/self-collision avoidance

- Co-Robot function: Hand-guide/collision detect stop

- NexCOBOT EtherCAT Master, CoE and DC supported

- Supports EtherCAT slave

NexMotion Studio

- EtherCAT devices offline edit and online scan

- EtherCAT master configuration

- PDO mapping edit

- Online SDO edit

- Export ENI

- CiA402 device operation: PP/PV/PT/CSP

- Single axis edit and operation

- Robot edit and operation

- I/O mapping edit and operation

- Provides simulation operation mode

A&D Inspection ProteX Series X-Ray Inspection Systems

The ProteX Series of X-ray equipment was designed for manufacturers striving to ensure maximum efficiency on their processing lines all within a compact footprint. Now, the most advanced aspects of product inspection can be incorporated into almost any point in production processes.

The new series uses the industry's most advanced imaging technology to provide high-detction sensitivity for a broad range of manufactring applications. Its enhanced imaging capabilities also consistently detect the smallest contaminants, while also conducting product integrity checks.

The A&D ProteX Series features the following benefits:

- The most compact design on the market makes integration painless

- Large 15" color touchscreen and intuitive interface for easy operation

- IP66 rating and easy-to-clean hygenic design

- Superior inspection algorithms include shape dectection, mass detection and enhanced contaminant detection

Find out how ProteX X-ray is making Inspection Simplified.

No nominations to this category

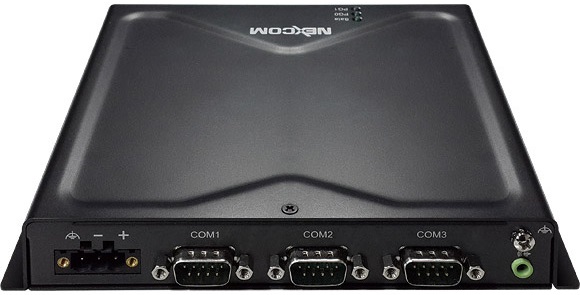

NEXCOM NISE 50-IoT Industrial Gateway

NEXCOM NISE 50-IoT industrial gateway is designed to acquire data from PLC or device in the field side, and upload or push it to the database or cloud. The industrial gateway could also take simple logic control without another computer. With these acquired data, it could help users improve their process parameters or predict machine maintenance schedule to reduce down time. The built-in application, IoT-Studio, helps speed up the development and deployment time.

- Ready-to-use IoT Gateway to accelerate IoT project deployment

- Easy connectivity via IoT studio, drag-and-drop managing data flow

- Connect up to 5 devices via Modbus TCP/RTU protocol for data acquisition

- Supports wired or wireless cloud connectivity via publish-subscribe-based MQTT protocol

- Open architecture supports both Windows-based and Ubuntu-based IoT Gateway

Hardy Dynamics CIP Checkweigher

The new Dynamic CIP is a specialized clean in place version of the Hardy Dynamics checkweigher designed to meet demands of food and chemical manufacturers. The new Dynamic Checkweigher CIP uses framework that minimizes horizontal flat surfaces, using sloped faces and round tubing where possible, and a sloped cabinet. An enhanced safety conveyer design minimizes entrapment and other hazards from rotating shafts or equipment. Changes to Hardy’s manufacturing techniques helped adapt the Dynamic Checkweigher to meet the sanitary and hygienic standards CIP clients require.

Hardy's Dynamic Series of checkweighing machinery is built using off-the shelf components, with controls based on a Rockwell Automation's CompactLogix platform, providing a standardized open source architecture that is flexible enough to meet both current and future control needs. Running Studio5000®, the GUI uses FactoryTalk View software, giving the user the ability to share and modify information presented on the machine’s HMI to the larger Rockwell The Connected Enterprise®. Extra onboard I/O and the ability to expand the rack provide a future proof control platform that is ready to accommodate additional upstream and downstream closed-loop controls, as well as peripherals such as metal detection and x-rays. All data tags are available to Enterprise wide software.

Weight processing is managed by Hardy’s HI 4050CW weight controller. Sampling weight data at 4,800 times per second, the HI4050CW is capable of providing enough weighments to accurately categorize packages weighing from 5g to 225kg at speeds up to 350 packs per minute.

Minebea Intec SPC@Enterprise

The software SPC@Enterprise combines classic filling quantity control with dynamic process control for a wide range of different systems, thereby efficiently supporting quality management of your production processes.

- Efficient networking of a diverse range of devices and systems from Minebea Intec and other vendors

- Fast process control due to powerful monitoring program

- Easily generate production or calibration statistics

- Simple data backup will return a lower risk of data loss

PT Limited PT100SBS-8 Junction Box

The PT100SBS summing boxes are high-quality summing boxes with individual load cell adjustment for the weighing industry with a durable stainless steel housing. Fitted with liquid tight strain relief cable fittings. The PT100SBS accepts a wide range of cable diameters. Enclosed in a tough stainless steel housing, easily accessible yet securely closed and positively sealed by way of its screw-on cover and external fixing holes. Designed and produced for the installer, with jumpers for summing without attenuation and simple to reach and positive control trim pots for load measurement correction. The 8 way also contains surge arrestors appropriate for weighbridge and large tank and silo installations.

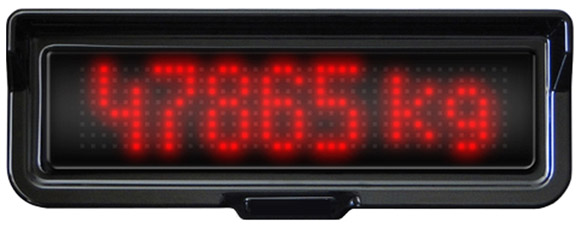

Zemic Europe Top-Sensors Display WA1

The Top-Sensors Display WA-1 is a display for scale output. This display is suitable for all Top-Sensors transmitters and has a eight-characters alphanumeric matrix. The digits have a height of 60 mm each and 32 LEDS per digit. This display shows 8 digits if the font is normal or 7 digits if the font is set to bold.

Detailed specifications Top-Sensors Display WA-1:

- Build-in Brightness regulation

- Build-in option to choose between 2 different fonts

- Opto-isolated RS232 interface

- Serial port RS485

- Opto-isolated current loop interface CL 20mA

- Ingress Protection: IP67

Suited for silo and weighbridge applications!

No nominations to this category