Automation Inside Awards 2019

Nominated for Best Measurement Systems

Minebea Intec X3 Weight Indicator

The verifiable Minebea Intec weight indicator X3 ensures fast and reliable display of the weight values. With the integrated EasyFill® application, filling with liquids, powders or granules can be controlled. Also especially suitable in combination with the Minebea Intec digital load cells.

- High-precision weight indicator offering a resolution of up to 120,000 increments

- Large, clearly readable display of weight values, even in direct light

- Convenient and efficient scale calibration in one minute without weights

- Remote configuration and service functionality through integrated website

- EasyFill® function for one-component dosing of liquids, powders and granules with configurable target, tolerance and overshoot values

- Multiple data interfaces allow easy integration into process control systems and direct connection of a printer or remote display

- Housing suitable for panel mounting

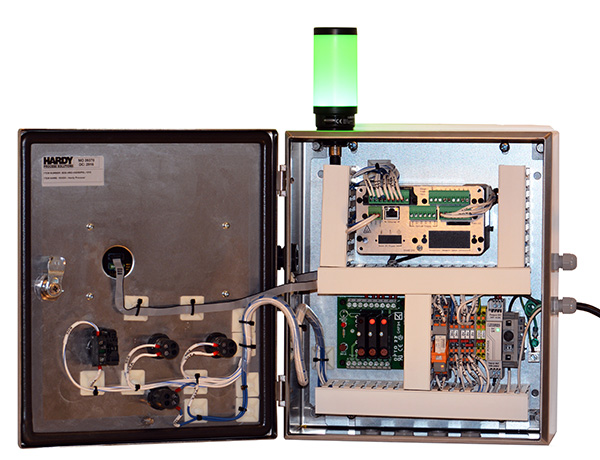

Hardy Integrated Panels

REDUCE THE TIME TO DESIGN, DEVELOP AND DEPLOY:

Hardy Process Solutions provides Integrated Panel Solutions for turnkey delivery of process weighing equipment in a variety of enclosures including stainless and powder-coated steel, in rectangular, watershed and hygienic designs. Integrated Panel Solutions ease ordering and save time in configuration and installation, enabling customers to get their measurement system up and running faster.

Delivered ready to install, panels come in a type 4 or 4X rated enclosure with pre-wired instrumentation, accessories and peripherals, and pre-cut gland holes and a wireway for a complete, clean and organized measurement system.

Integrated Panel Designs Include:

- Installation of Hardy HI 4050, HI 6500, HI 6500-XP, or HI 6600 series instruments configured with any number of options, mounted on DIN Rail in a hinged type 4 or 4X enclosure with the associated pass through glands for power, communications, up to four sensors and up to three output cables.

- Installation of an optional display panel mounted in the center of the upper half of the enclosure door allows an area for buttons and switches to be located in the lower half of the door.

- Installation of an optional Hardy HI6020IT summing card with connectors mounted in the back of the enclosure.

- Nine standard enclosure options are available in a variety of materials, shapes and sizes, Other sizes and types are available by request.

Optional Components Include:

- 22mm metal pushbuttons and associated indelible marking. Available buttons are currently Blue (reset), Black (zero) and White (tare) and are located at the bottom half of the enclosure door

- N-position selector switch and associated indelible marking to indicate modes of operation for Gross or Net located in the enclosure door

- 3-mode tower light wired to the instrument located on the top of the enclosure

- Opto22 relay backplane to accommodate a large variety of relay choices in AC, DC, low and high current, mechanical and solid state

EASY INSTALLATION:

Just hang the Integrated Panel Solution on the wall, connect your load cells to the built in summing card through the cable glands and you are ready to calibrate!

The embedded webserver in the instrument enables access to setup and calibration from anywhere on your network. Use Hardy's exclusive C2® for automatic system calibration to save hours in commissioning and routine maintenance.

Use INTEGRATED TECHNICIAN® to maintain and troubleshoot the weighing system from anywhere in the world or use Hardy’s intuitive local display.