Rockwell Automation (USA) - Terminal delivers efficiencies, enhanced visualization for operators and machine builders.

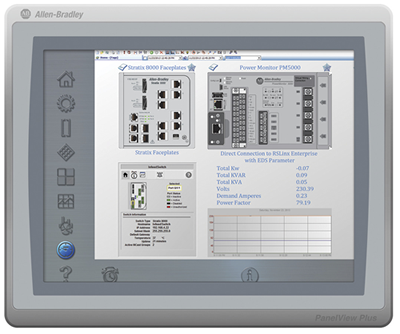

Rockwell Automation announces the release of the Allen‑Bradley PanelView Plus 7 Standard graphic terminal, giving machine builders new options in the size, functionality and connectivity of their graphic terminals. The terminals are available in five screen sizes, including widescreen options.

“As facilities work toward achieving a Connected Enterprise, machine operators are relying on graphic terminals more than ever to monitor and react in real time to a growing amount of critical data,” said Scott Oakley, global product manager, Rockwell Automation. “We’re introducing a wider range of terminal options and increasing screen resolution to help ensure data can be quickly and easily viewed in a manner that best fits each user’s application.”

The PanelView Plus 7 Standard operator interface is available in screen size options ranging from 4 to 10 inches. Widescreen formats are available for the 4-inch and 9-inch screen options for enhanced visualization.

Plant operators can take advantage of the mobile capabilities of the PanelView Plus 7 Standard terminal to monitor data from anywhere on the plant floor using a tablet, smartphone or other mobile device. Virtual network computing (VNC) connectivity also supports secure application monitoring on mobile devices from remote locations.

To more efficiently configure multiple machines, machine builders can save projects to the PanelView Plus 7 Standard SD card. This eliminates the cumbersome process of configuring the same project for multiple machines. Users can save their operating system, network configuration, data logs, recipes and other files to the SD card to quickly restore operations in the event a terminal needs to be replaced. Operators also can access saved diagnostics, including messages, alarms and warnings, to better troubleshoot problems and support proactive maintenance activities.

The Rockwell Automation software library of code now includes faceplates and add-on instructions (AOI) for the PanelView Plus 7 Standard operator interface to help machine builders save development time. This addition to the library can reduce complex screen-development time by as much as 90 percent.

New installation clamps support fast, simple terminal installation and removal without the use of tools. This reduces installation and maintenance time, and minimizes the risk of over tightening and damaging the terminal during installation.

The PanelView Plus 7 Standard terminals provide connectivity to one controller, and up to 25 screens and 200 alarms along with ATEX Certification. These features complement the Allen-Bradley CompactLogix 5370 programmable automation controllers and work with the FactoryTalk View Machine Edition (ME) software from Rockwell Automation to simplify project maintenance and better handle multiple applications on a single terminal.

This website uses cookies. By browsing our website you accept the use of cookies. For more information read our Terms of Use.

Enhanced Resolution and Widescreen Options With PanelView Plus 7 Standard Operator Interface from Rockwell Automation

- By Rockwell Automation

- Posted on Feb 02, 2015

For more information about this article from Rockwell Automation click here.

Other articles from Rockwell Automation.

Interesting Links:

GameMarket.pt - Your Gaming Marketplace with Video Games, Consoles, PC Gaming, Retro Gaming, Accessories, etc. !

Are you interested on the Weighing Industry? Visit Weighing Review the First and Leading Global Resource for the Weighing Industry where you can find news, case studies, suppliers, marketplace, etc!

Are you interested to include your Link here, visible on all AutomationInside.com articles and marketplace product pages? Contact us

GameMarket.pt - Your Gaming Marketplace with Video Games, Consoles, PC Gaming, Retro Gaming, Accessories, etc. !

Are you interested on the Weighing Industry? Visit Weighing Review the First and Leading Global Resource for the Weighing Industry where you can find news, case studies, suppliers, marketplace, etc!

Are you interested to include your Link here, visible on all AutomationInside.com articles and marketplace product pages? Contact us

© Rockwell Automation / Automation Inside

Previous article

Force Torque Sensor Application Demo with Robotiq FT 150

Next article

RNA New Linear Feeder SLA

Popular News

Automation Inside Newsletter

Popular Tags

Login

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.