Automation Inside Awards 2021

Nominated for Best Sensors

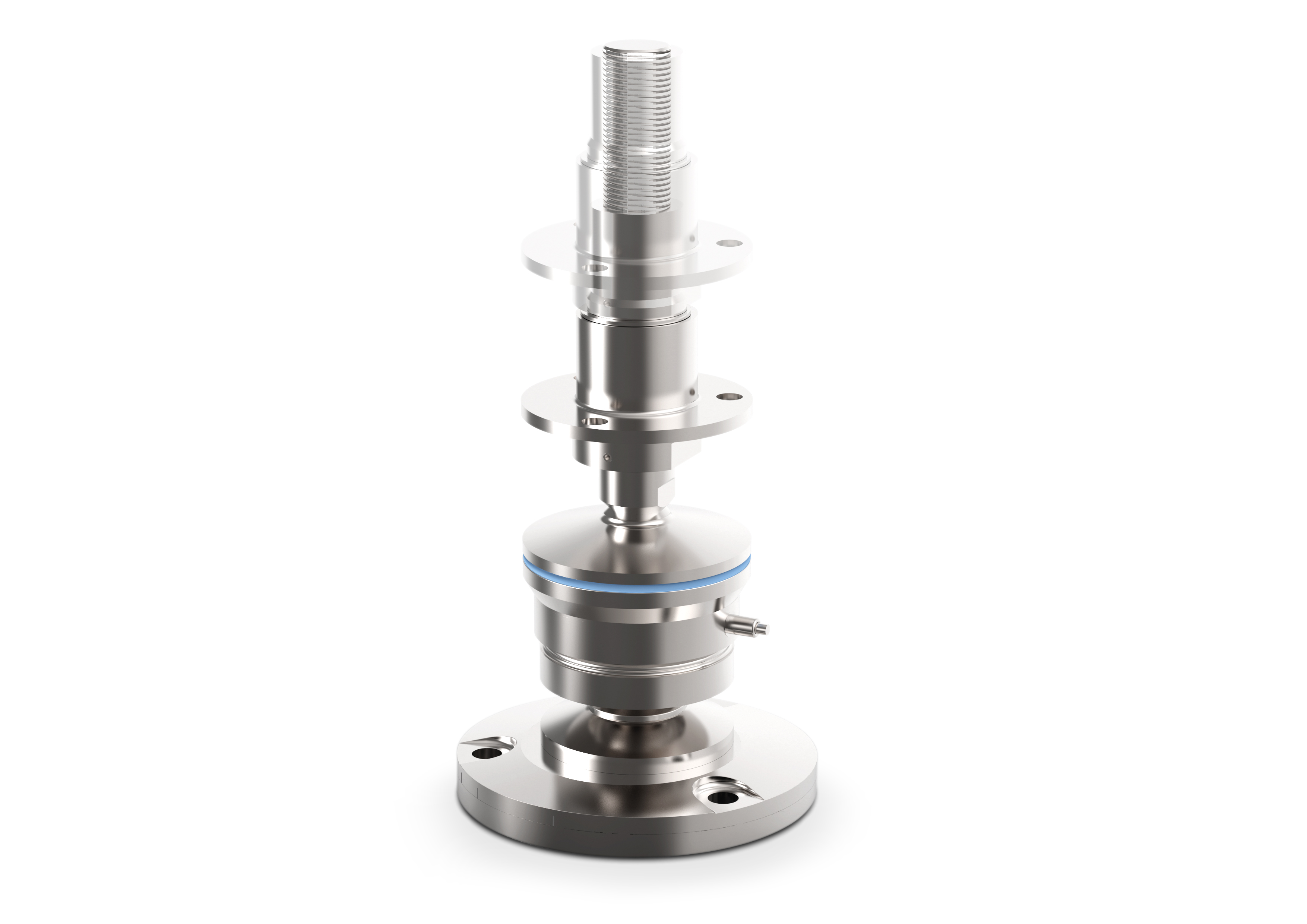

Utilcell Mod. 300 (5…500 kg) – High accuracy for weighing tanks and hoppers

UTILCELL (Spain) - The load cell Model 300 (5...500 kg), together the mounting kit, have been designed for robust and accurate weighing in industrial processes of tanks and hoppers, with multiple advantages:

- Stainless steel, hermetically-sealed load cell with the highest protection grade IP 68/IP 69K.

- Globally used in legal weighing systems. OIML Class C 3000 to 6000 div. and NTEP Class III & IIIL 4000 to 10000 div, single or multiple load cells.

- Highly recommended load cell for any type of tanks and hoppers in industrial weighing applications.

- High repeatability and high accuracy of the weighing values.

- Improved force transmission to the load cell due to a ball-based joint, giving the best accommodation in cases of thermal expansions, structural torsions and deflections.

- Superior safety systems for the utmost reliability:

- Easy installation in the tank and hopper supports, with or without the load cell

- Blockage bolts for transport protection of the load cells

- Upper plate with conical holes for self-centering

- Integrated lift-off prevention system

- Cable-entry protection plate for impact protection during commissioning and in transited zones

Thames Side Sensors MasterMount®

The MasterMount® is a unique, patented and cost-effective load cell/mounting accessory combination for silo, tank, hopper or vessel weighing. Installation is made easier, safer and much faster using this simple innovative design. Load cell installation/replacement can be carried out in only a few minutes.

A high precision stainless steel VC3500 double shear beam load cell, protected to IP68/IP69K, combines with a painted alloy steel weighing module having an integrated cam mechanism. This is an ideal combination for applications requiring wash-down cleaning, even in hazardous (ATEX/IECEx) areas. The load cell’s ATEX certification eliminates the need for safety barriers in dust zones 20, 21, 22.

No specialist tools or lifting equipment is necessary to raise the weighing vessel, install a load cell, then lower the vessel again – even when it is full. The lifting and lowering is carried out by the weighing module itself. This reduces the list of tools required for installation and increases safety.

This is a cost-effective solution, designed to simplify the installation work of weighing system integrators.

Minebea Intec Novego® Weighing Module

The weighing module Novego® was specifically developed to meet the increasingly stringent requirements of the food industry. This hygienic all-in-one solution boasts a range of innovative properties to ensure simple, error-free installation and maximum resistance to lateral forces.

- Hygienic weighing module ensures efficient cleaning

- High degree of process reliability and precision thanks to the innovative side-force-resistant system

- Quick and easy commissioning due to smart add-on parts

- Durable, reliable weighing solution with excellent corrosion resistance