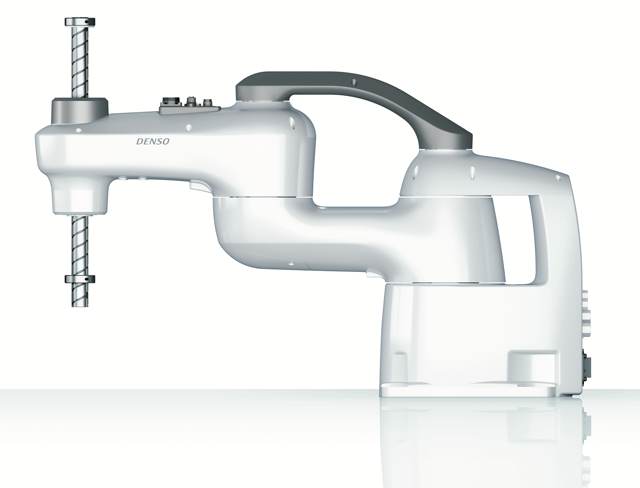

The new DENSO HSR Series four-axis SCARA robot uses advanced vibration control, a newly designed, highly rigid lightweight arm and improved heat dissipation in the base unit to achieve new levels of continuous high-speed performance and repeatability.

The HSR Series uses advanced vibration control, a newly designed, highly rigid lightweight arm and improved heat dissipation in the base unit to achieve new levels of continuous high-speed performance and repeatability:

- Quick Acceleration

- Runs continuously at high speed

- Stops precisely

Continuous high-speed performance that changes everything:

Reduced shaft whip and settling time, along with a lighter-weight arm and an optimized arm structure make the HSR robots more efficient than previous models, enabling them to accelerate faster, run continuously at their maximum rated speed and stop more precisely. Standard cycle time (with a 2-kg weight) is from 0.28 to 0.31 sec. and repeatability is from ±0.01 to ±0.012 mm. Maximum payload capacity is 8 kg, with available reaches of 480, 550, and 650 mm. Applications include high-speed, high-precision pick and place in assembly processes, as well as packaging processes in the food, medical device, pharmaceutical and cosmetics sectors.

Features:

- High-speed motion - Optimized acceleration and motion profiles: Improved high-speed motion results in more cycles per minute (CPM) and therefore higher productivity

- Continuous motion - Achieving continuous, non-stop motion: Improved heat dissipation in the base unit allows the robot to run continuously at its highest rated speed, a requirement in today’s demanding processes

- Vibration control - Vibration-control technique for suppressing vibrations: The robot quickly suppresses vibrations by actively reflecting the status of the arm to the controller’s vibration control. Vibrations that occur during high-speed transfer as well as residual vibrations are both suppressed, reducing cycle times

- Light weight - Newly designed, highly rigid lightweight arm: The combination of high rigidity and light weight allow the robot to handle a high payload of 8 kg and achieve high-speed motion at the same time

- Flexible mounting configuration: The HSR robot is available in both floor- and ceiling-mount models

- Optimum layout - Optimized arm design allows the robot to achieve continuous high-speed motion: A large-capacity motor is integrated into the base unit. Weight reduction of the arm and an optimized arm design allow the robot to achieve its continuous high-speed performance

Options:

- Wiring protection kit - Protects external wiring to prevent cables from becoming unorganized, avoiding the risk of broken wires

- Built-in Ethernet - An Ethernet cable is built into the body and is easily connectable to external devices. Ethernet connectors (sold separately) are available as options

- External battery - The encoder backup battery is installed outside the robot, facilitating maintenance and replacement of batteries

- Stopper with bearing - Protects wiring installed through the hole of the bearing located at the top of the Z-axis shaft

Video:

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.