Serial EtherNet/IP Linking Devices from HMS Industrial Networks:

The new serial EtherNet/IP Linking Device makes it possible to include any automation device with a serial RS-232/422/485 application interface in an EtherNet/IP-based network architecture. It supports all kinds of serial protocols including Modbus, DF1, produce/consume, ASCII and custom protocols.

Besides being a more cost-effective alternative to in-chassis communication modules, the distributed EtherNet/IP Linking Device also brings other advantages:

Improved system architecture:

Contrary to an in-chassis module which is physically connected to the PLC, the Linking Device can be mounted close to the connected machine. This means that it is possible to establish a connection via a single Ethernet cable instead of multiple network specific cables. The Linking Devices support ODVA’s Device Level Ring (DLR) for ring topology.

Easier configuration:

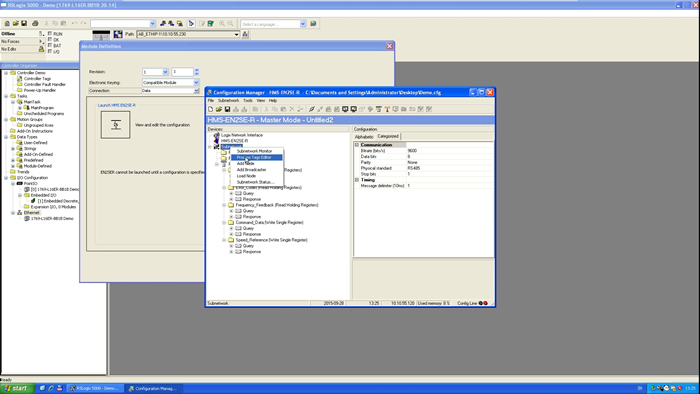

Users access serial protocol configuration through their existing Studio 5000 software. All configuration is made inside Studio 5000 where there is support for Process Variable Data Tags and manual and automatic generation of named and structured Studio 5000 Controller Tags without any required user logic.

High performance and stability:

Since the Linking Devices are stand-alone (distributed), they do not affect PLC backplane performance (PLC execution time), even when large amount of data is transferred. The PLC simply scans the Linking Device as if it were any other I/O device on the network

Easier system integration:

“After first communicating about the EtherNet/IP Linking Devices in 2015, we have seen a great interest from the market in these solutions,” says Kevin Knake, Executive Vice President, HMS Inc. “The Serial EtherNet/IP Linking Device is the first step in our Linking Devices program and we will add versions for PROFIBUS and Modbus TCP later during 2016. With the Serial Linking Device, we can offer a cost-efficient solution with a very tight integration to Studio 5000 which will give many Rockwell users easy access to serial devices such as variable frequency drives, barcode scanners, process instrumentation and weight controllers.”

All configuration is made from inside Rockwell Automation’s Studio5000 Logix Designer.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.